PARKING LOTS

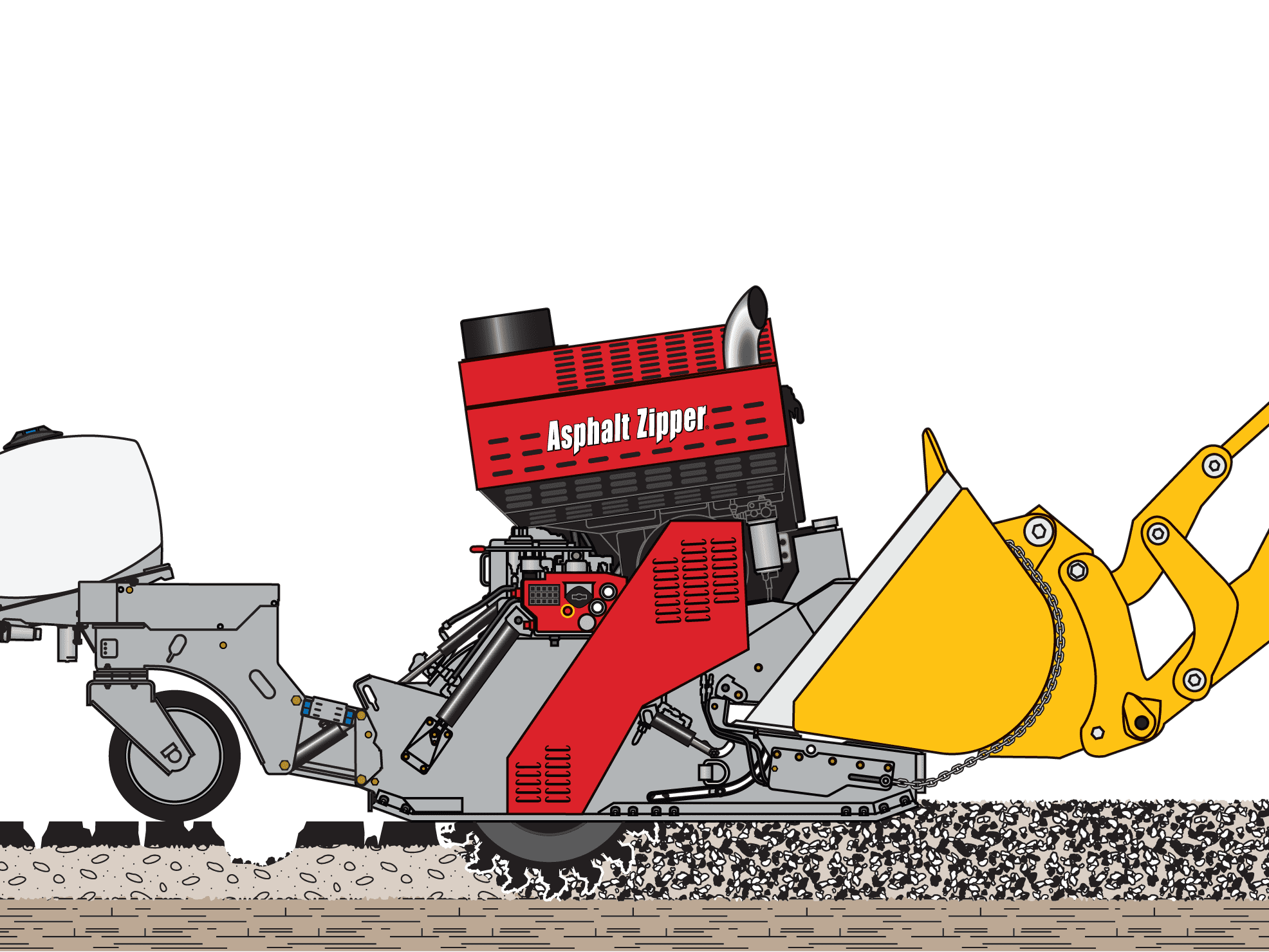

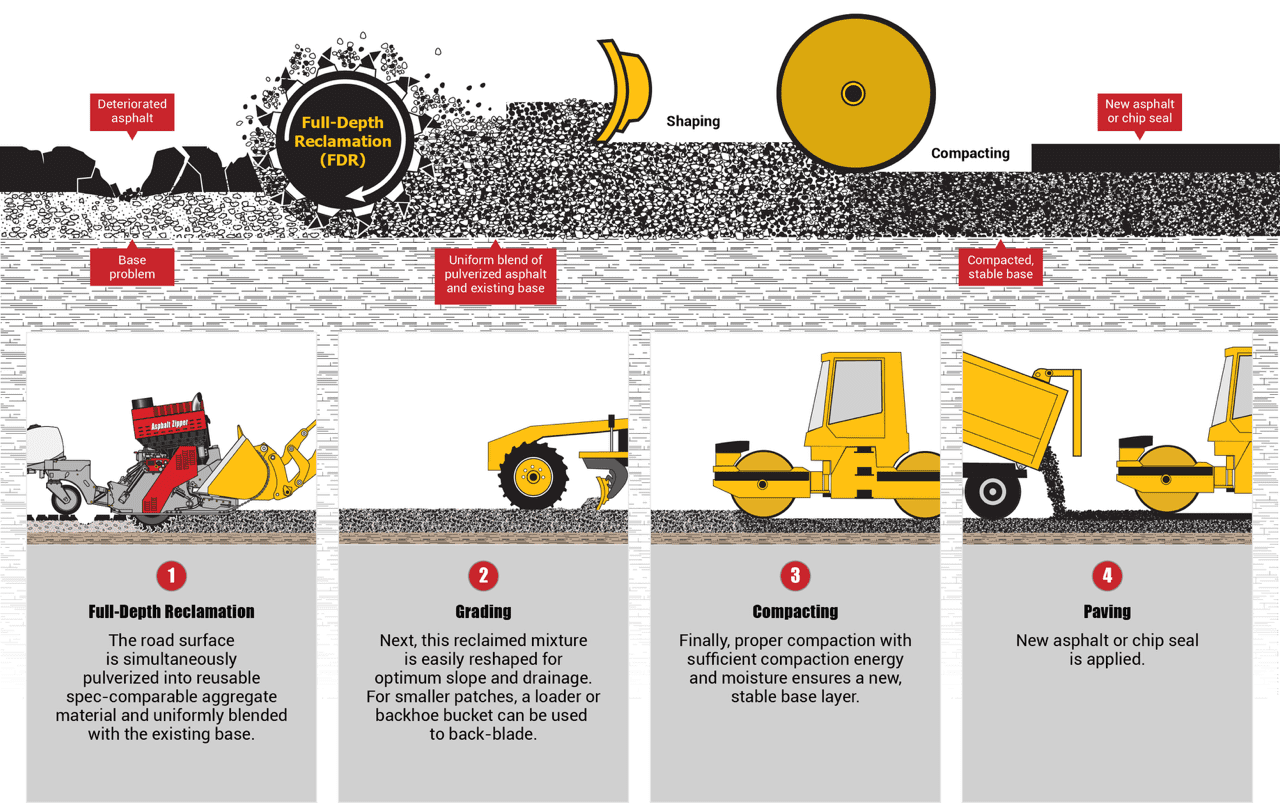

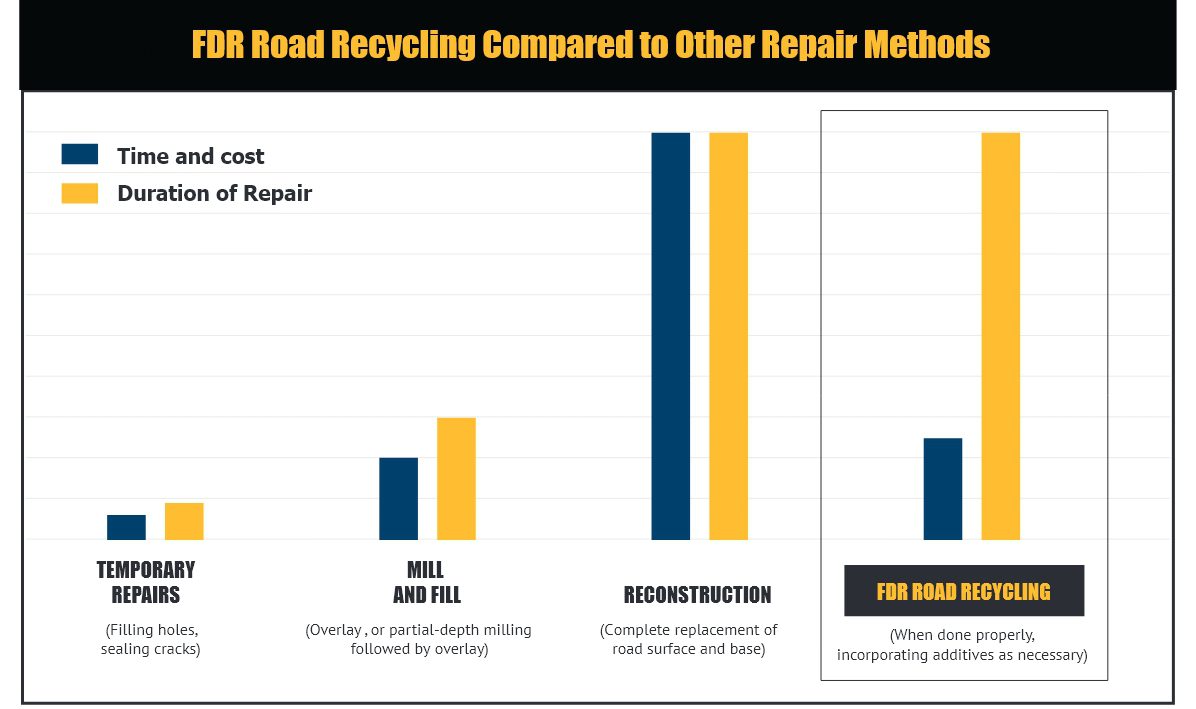

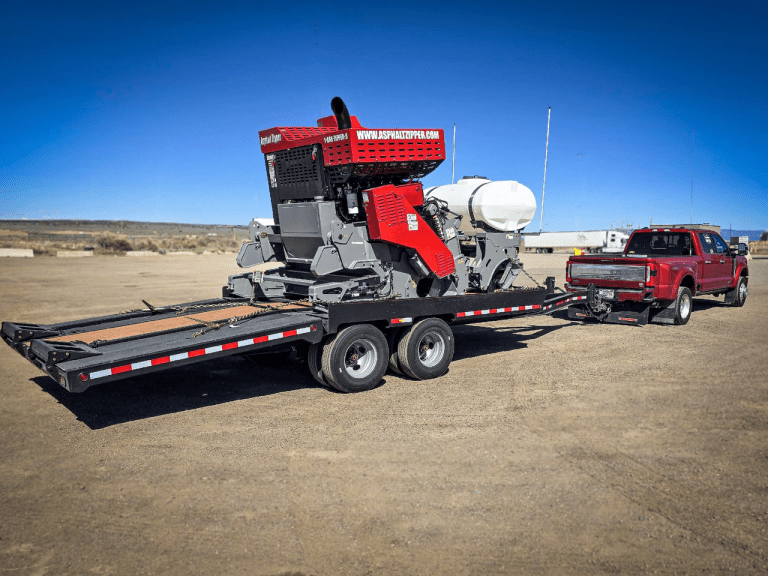

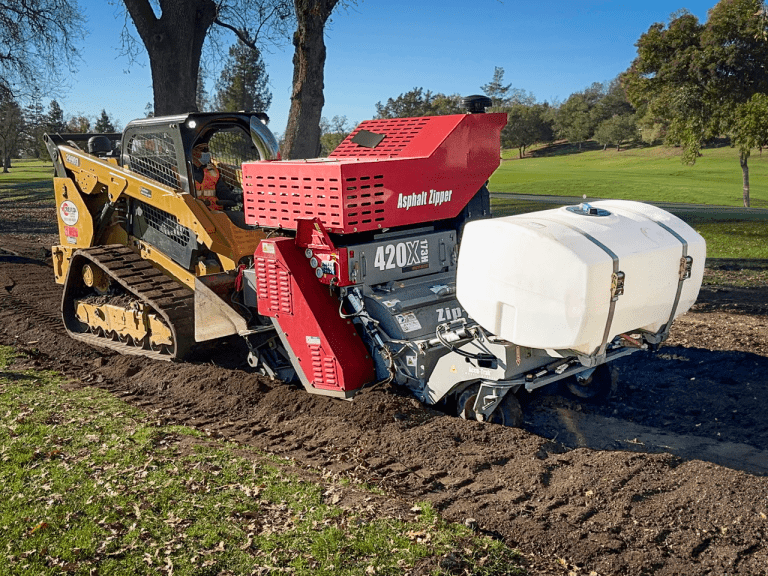

Parking lot repair has never been easier. Now complete many repairs in less time than it takes to transport a larger self contained machine to the job site. You can quickly and easily pulverize parking lot surfaces into spec comparable material and simultaneously blend with the underlying base. This improves the load bearing capability and durability of the parking lot base for a small fraction of the cost and time of reconstruction, using the existing materials.

Need even greater stability? Easily incorporate additives such as Portland cement, lime, emulsions, polymers, etc. Asphalt Zipper’s unmatched blending capability combined with a built in spray system or an optional metered liquid injection system make it easier than ever to blend both dry and liquid stabilizers.

Best of all, do parking lot repairs that used to take weeks in as little as a day or less. Many contractors opt to “Zip” at night and have the newly stabilized and smooth base ready for paving first thing in the morning. This is especially crucial for high value parking lots, keeping disruptions to a minimum.

Unlike larger asphalt milling machines, Asphalt Zipper machines are far more agile and easy to maneuver. You can now easily navigate around obstacles such as light poles and landscape islands and also work in tighter areas.

Full-depth reclamation in parking lots can also correct previous drainage issues, irregular grade, and increase overall smoothness.