FULL-WIDTH ROADS

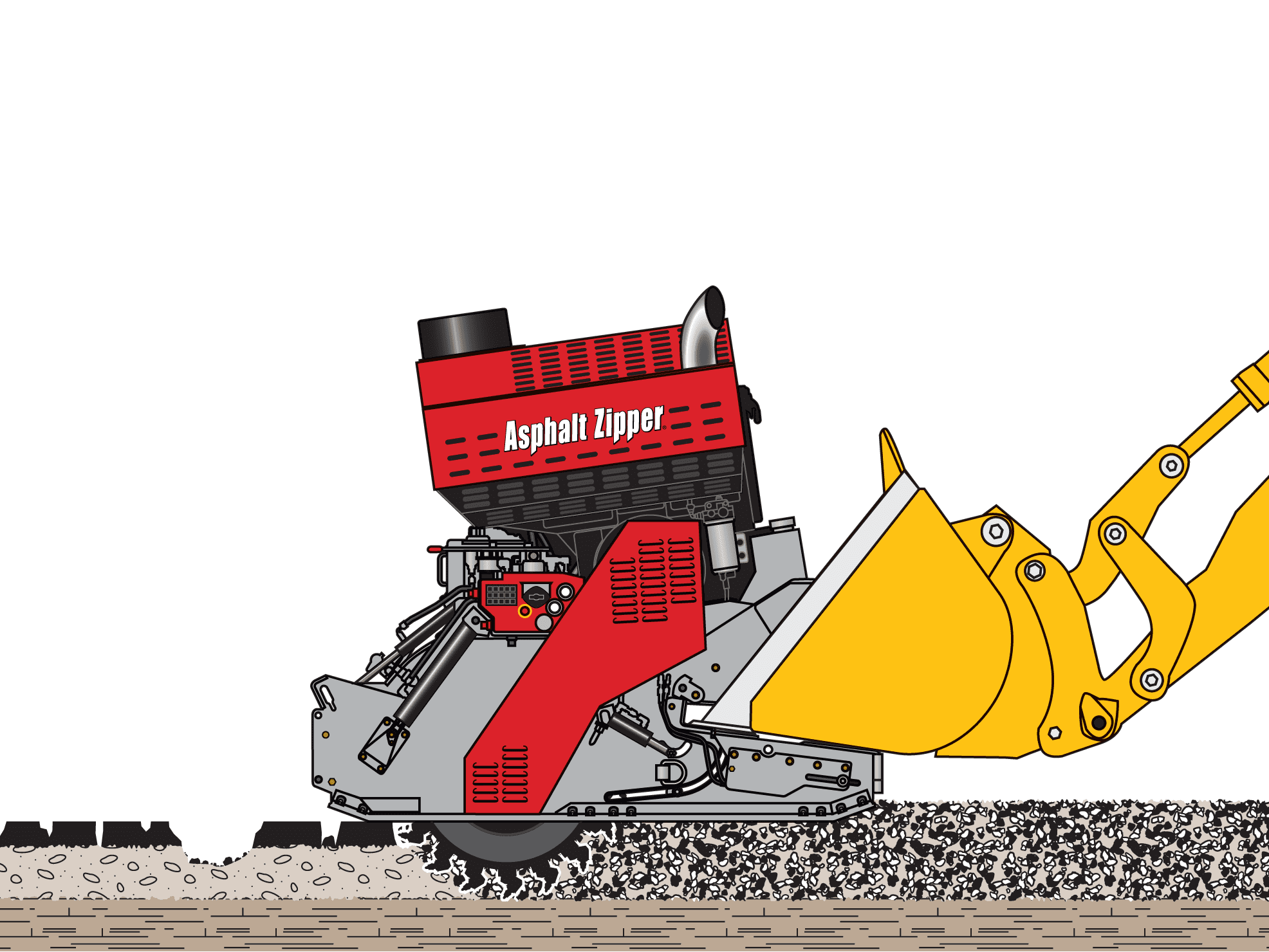

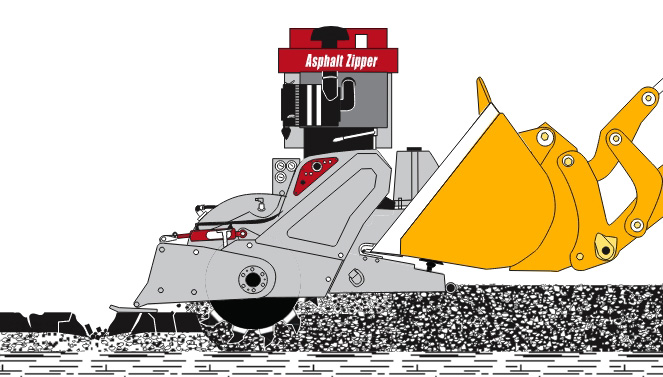

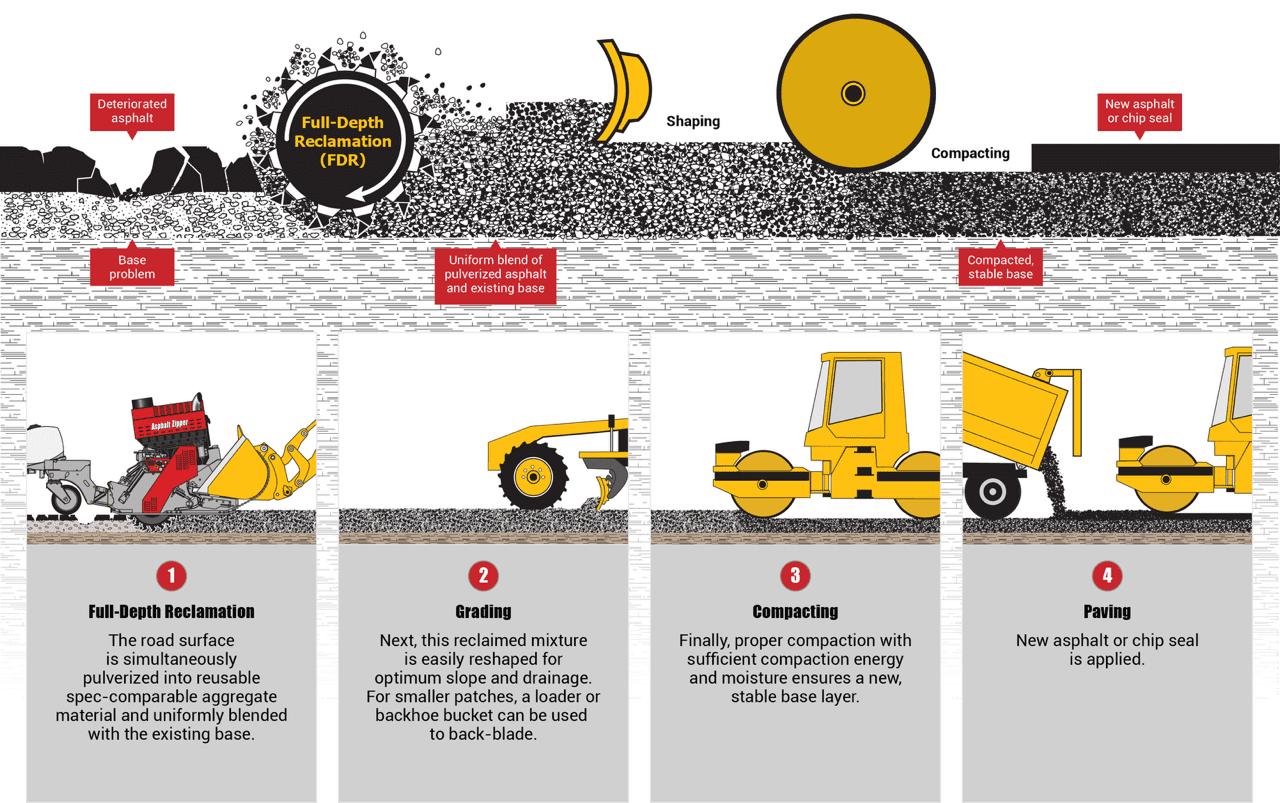

Don’t let the compact, easily maneuverable size of an Asphalt Zipper road reclaimer fool you. Sure, it’s perfect for smaller road patches and repairs, but it’s also just as formidable at tackling entire roads.

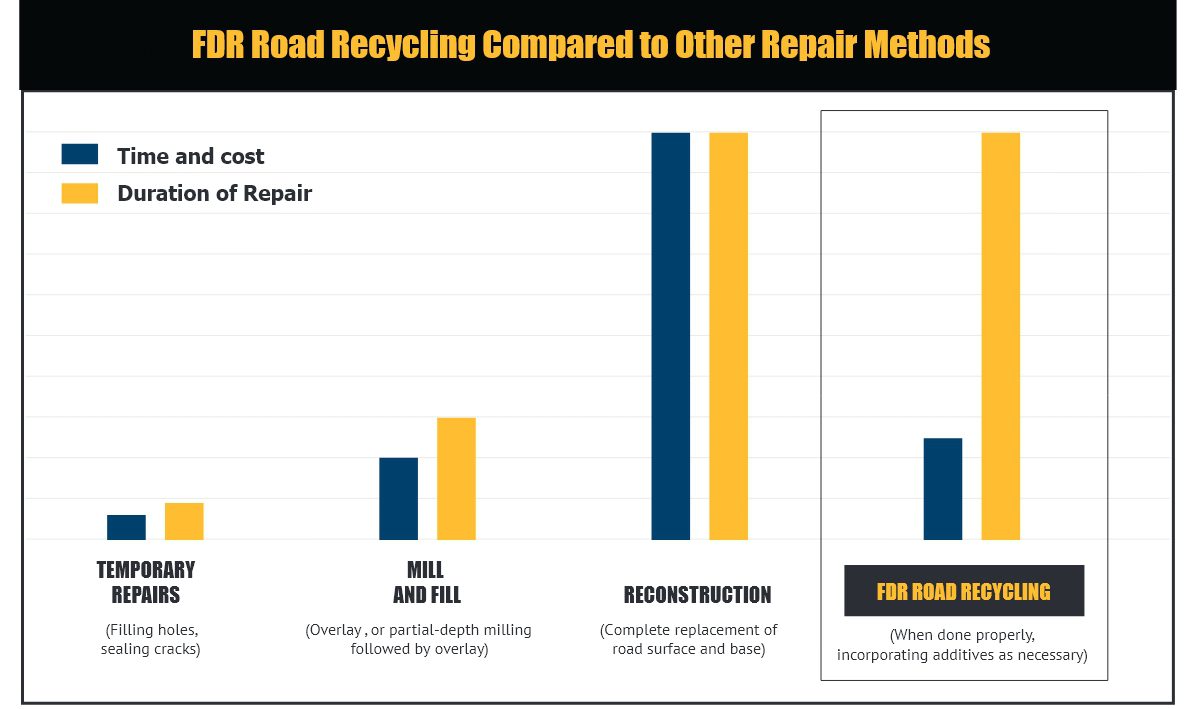

You can easily repair a full city block in as little as an hour and up to two miles of full width road in as little as one day. Best of all, when done correctly, you can realize all of the benefits of road reconstruction for a small fraction of the cost and time.

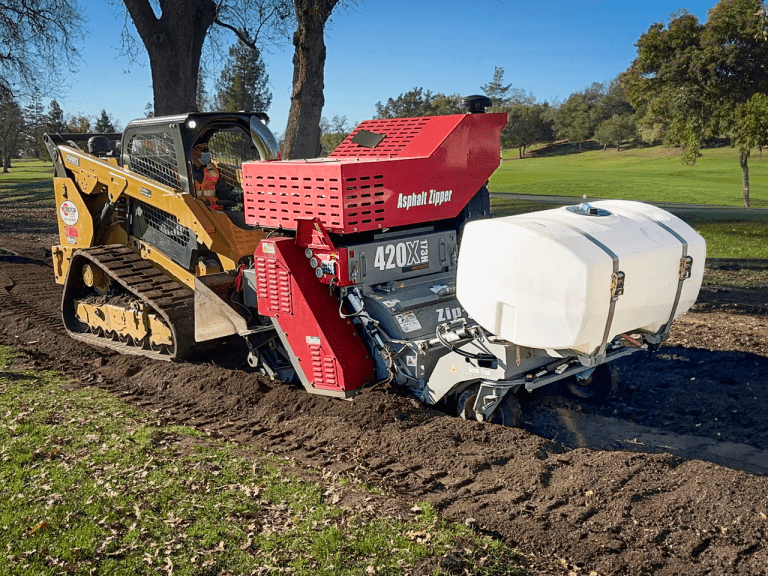

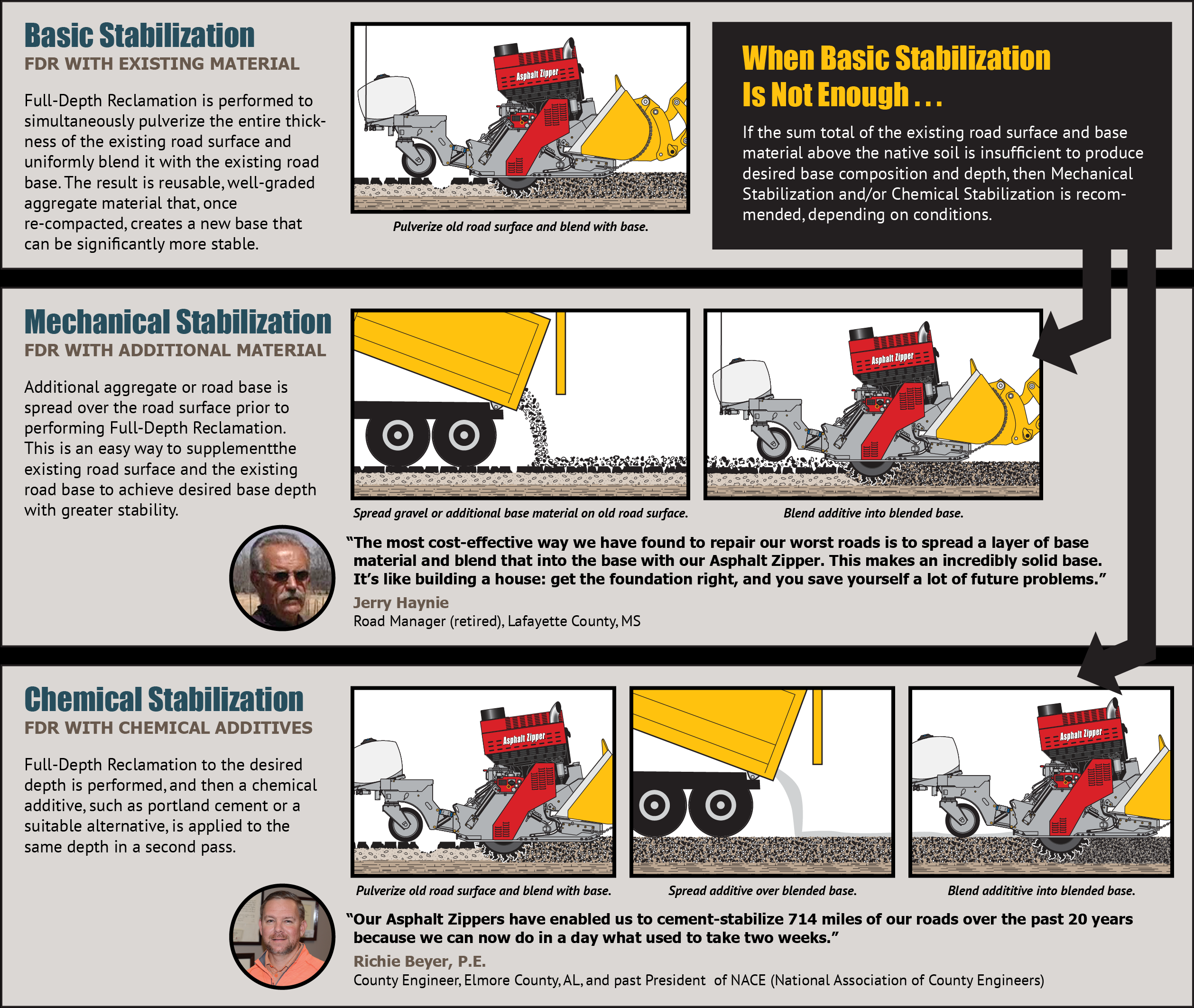

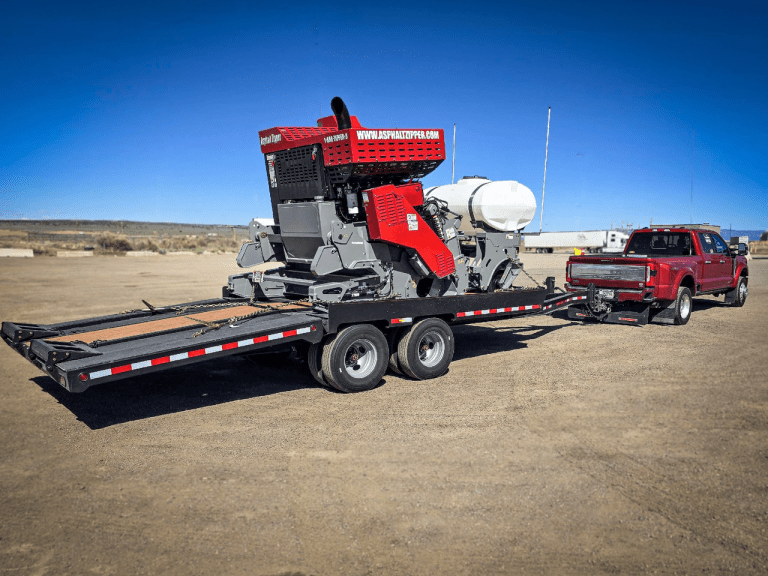

Models are available with standard cutting widths from 30 inches to 8 feet wide. Not only are Asphalt Zipper reclaimers perfect for doing Full Depth Reclamation but also a wide range of stabilization projects with countless additives. All machines come with on-board spray systems. Optional machine or hitch mounted water supply systems ranging from 100 to 300 gallons are available. You can even accurately deliver precise amounts of liquid stabilizer from a water truck with the optional AccuFlow™ metered liquid injection system.

Most models easily transport behind a work truck on their own custom trailer that is optimized with a low center of gravity for smooth towing. Now you can get to job sites quicker, potentially visiting several job sites in the same day.