A small contractor may wonder if a portable asphalt milling machine / asphalt grinder is worth it for one job. Portable asphalt milling attachments quickly connect to skid steers, backhoes, or loaders. Contractors can use them for utility trenching, road repair, full-depth reclamation, and asphalt surface milling projects. Here’s why they’re worth the investment, even for one job:

1. Increased Efficiency and Cost Savings on the Job

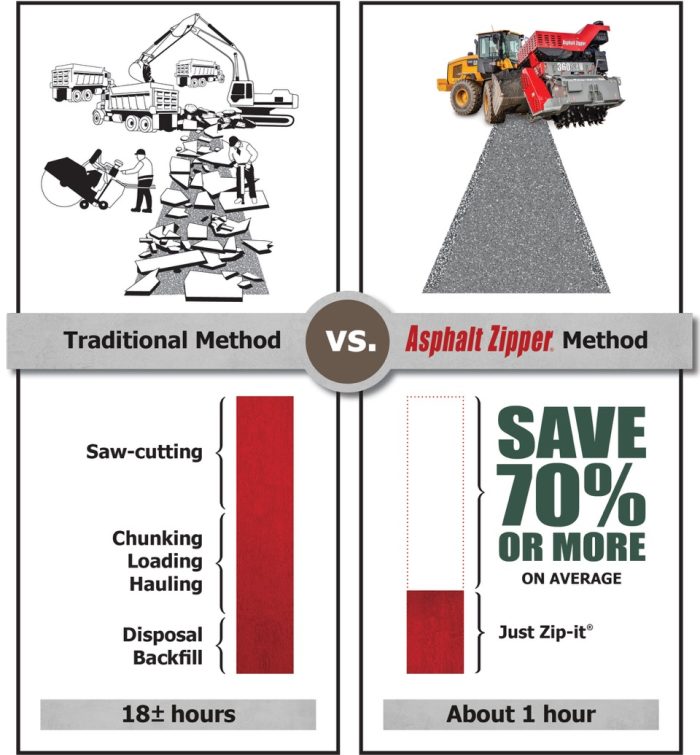

- A traditional asphalt removal job involves saw cutting, chunking, loading, and hauling away the asphalt road surface. This process requires multiple pieces of equipment and additional manpower. An asphalt grinding machine virtually eliminates these steps by grinding the asphalt into spec-comparable material. Fewer steps in the asphalt removal process leads to quicker completion times and cost savings.

- In fact, with a portable asphalt milling machine, you can save $1,000 on every 100 feet of asphalt you remove from a utility trench. Plan on an 8+ hour project using traditional asphalt removal steps taking 30 minutes with an asphalt grinder.

- You probably already have the equipment and manpower to saw cut your asphalt. Another piece of equipment could seem like a risk instead of an investment. But with the right equipment, you can make more money for your time and bid on more projects in the future.

- An asphalt milling machine can have several uses on the same utility trenching project. The variable hydraulic depth control of an Asphalt Zipper makes it ideal for trench plate recessing and t-cuts. If your job requires utility trenching and trench plate recessing, you can do both with one machine.

- If you own an asphalt grinder, you avoid the hassle of renting equipment. If you own your own asphalt milling machine, you won’t need to worry about project delays or extra rental fees. You can also mill just the asphalt you need, when you need it.

- Asphalt disposal is a real challenge for utility contractors. A portable asphalt grinding attachment creates spec-comparable recycled asphalt product (RAP) from existing material. Some project specs allow you to use your asphalt millings for trench backfill on your current project. This is environmentally friendly and cost-effective.

- If you do need to remove the asphalt millings, they are much easier to transport and dispose of than large chunks of asphalt material. This means that you can still save on hauling and disposal fees. You may be able to sell your asphalt millings or save them for trench backfill or road base material on other jobs. Landscaping companies regularly sell recycled materials such as asphalt millings for driveways and parking lots.

2. Future Job Flexibility and Service Expansion

- Open opportunities for a wide range of projects including asphalt repair, trenching, road widening, and parking lot maintenance projects. An Asphalt Zipper that opens utility trench can also do asphalt repair. It functions as a road reclaimer, doing full-depth reclamation, road stabilization, and soil stabilization projects on paved surfaces or gravel roads.

- These asphalt milling machines are maneuverable in parking lots and small enough to fit in alleys. Some models attach to the front of a skid steer loader. The narrower width gives contractors the ability to reclaim even golf cart paths.

- A portable asphalt milling machine or road reclaimer becomes part of your service offering. This allows you to expand into road construction projects like pavement recycling or road repair.

3. High Quality and Client Satisfaction

- Instead of outsourcing asphalt removal work, contractors can often achieve better results in-house. This gives them more control over the asphalt grinding process and the project schedule. In turn, they achieve higher customer satisfaction and potential referrals.

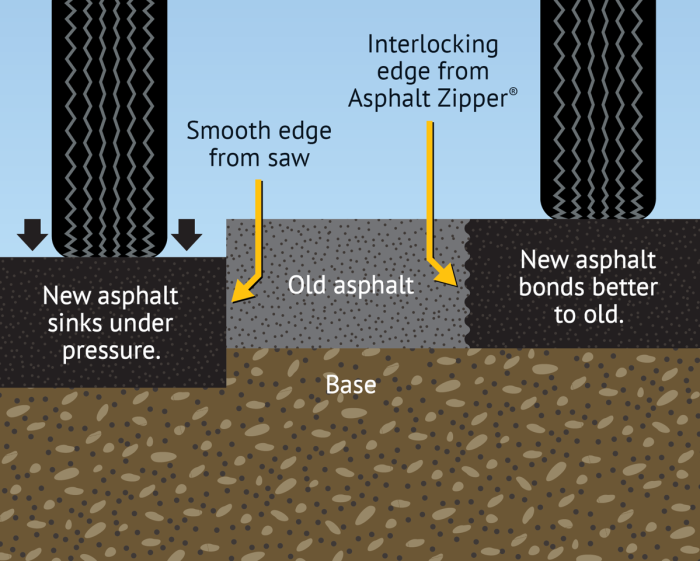

- Utility trenches cut with an Asphalt Zipper have a unique interlocking edge that bonds better with new asphalt. This helps to prevent asphalt failure along utility trench lines later on, especially on roads with high traffic loads

- A portable asphalt milling machine pulverizes the asphalt over the utility trench into spec comparable material. This material is easy to drive over. It gives almost constant access to business and residential areas during the construction process.

- If you own your own asphalt grinder, you don’t have to open miles of utility trench at a time. You have the flexibility to open only the utility trench you need to open in one day. This avoids unnecessary traffic delays.

4. Reduced Dependence on Subcontractors

- By owning an Asphalt Zipper, you can handle asphalt milling in-house rather than hiring a subcontractor. This reduces costs and increases profit margins.

- Scheduling subcontractors can be a challenge. When you have all the equipment you need to finish the job, you don’t have to coordinate with a sub-contractor. You could even consider subcontracting asphalt removal work yourself when you finish your job.

The decision to purchase an Asphalt Zipper comes down to weighing the initial cost against its cost effectiveness. For a contractor planning to stick with asphalt-related work, this machine is a great long-term investment.