Full depth reclamation, or FDR, is a road repair and road base repair method. A road reclaimer or road milling machine pulverizes worn asphalt while mixing it with the road base.

Full depth reclamation fixes road surface problems like potholes and alligator cracking by fixing the road base. This results in long lasting and durable repairs. This post explains full-depth reclamation for those considering doing it instead of surface patching or full road reconstruction.

Full-Depth Reclamation (FDR) is a sustainable road repair method used to renew worn asphalt pavement. Traditional road repair methods involve removing the old pavement entirely and replacing it with new materials. FDR recycles the existing pavement structure as road base, creating a stronger and more durable road.

FDR pulverizes the existing pavement along with a certain depth of underlying road base. Sometimes it involves blending this mixture with a stabilizing agent, such as cement or asphalt emulsions.

Crews then compact and grade the pulverized mixture to create a strong, durable base for a new pavement surface. FDR results in improved pavement performance, making it a popular choice for road rehabilitation projects.

History of Full Depth Reclamation

Full-depth reclamation has been around in some form or other for decades. Originally, rippers attached to motor graders or tractors scarified existing layers of asphalt pavement into large chunks. Grind rollers then reduced these chunks into smaller pieces. Starting in the 1950s, road crews used large rotary mixers to further reduce the size of the ripped pavement.

Next, companies developed cold planers and asphalt milling machines that removed asphalt pavement layers to specified depths. This in turn led to the development of large asphalt reclaimers or road reclaimers.

Much like a cold planer or asphalt milling machine, road reclaimers have a large drum with carbide cutting bits or teeth. These drums pulverize the existing asphalt and mix it with the road base in one step.

Road reclaimers come in a variety of sizes. Unfortunately, larger ones can have limited cost effectiveness for small organizations. Portable road reclaimer attachments that connect to a backhoe or loader can be significantly less expensive than larger machines. The development of portable road reclaimer attachments makes in-house full depth reclamation possible for even small cities and towns.

Methods of FDR

Organizations can choose between three types of full depth reclamation: basic, mechanical, and chemical stabilization. Road base, soil type, and pavement conditions determine the best FDR method for each project.

Basic stabilization is fairly straightforward and uses only the existing material. First, a road reclaimer pulverizes the existing asphalt into recycled asphalt product while mixing it with the road base. Next, road crews grade the new road base material and compact it, using water as needed. Finally, crews apply a surface treatment of paving or chip seal to the entire surface.

When basic stabilization is not enough, many crews use mechanical stabilization. With this method, road crews spread gravel or other road base on the surface of the asphalt before FDR. Then they pulverize the existing asphalt surface with both the added material and the existing road base.

The third type of FDR is chemical stabilization. Chemical stabilization includes an extra step to create added road base stability. First, crews complete basic stabilization, pulverizing the existing asphalt with the road base.

Next, they spread a chemical additive such as Portland cement or an emulsion over the recycled materials. Finally, they blend the additive in a third pass with their road reclaimer.

Benefits of Full Depth Reclamation

Full depth reclamation is an environmentally friendly road repair. By mixing recycled asphalt with the base layer, full depth reclamation reduces asphalt waste in landfills. It also conserves natural resources by removing vehicle emissions involved in transporting asphalt waste. Finally, by using existing product, full depth reclamation avoids the production of additional aggregate material.

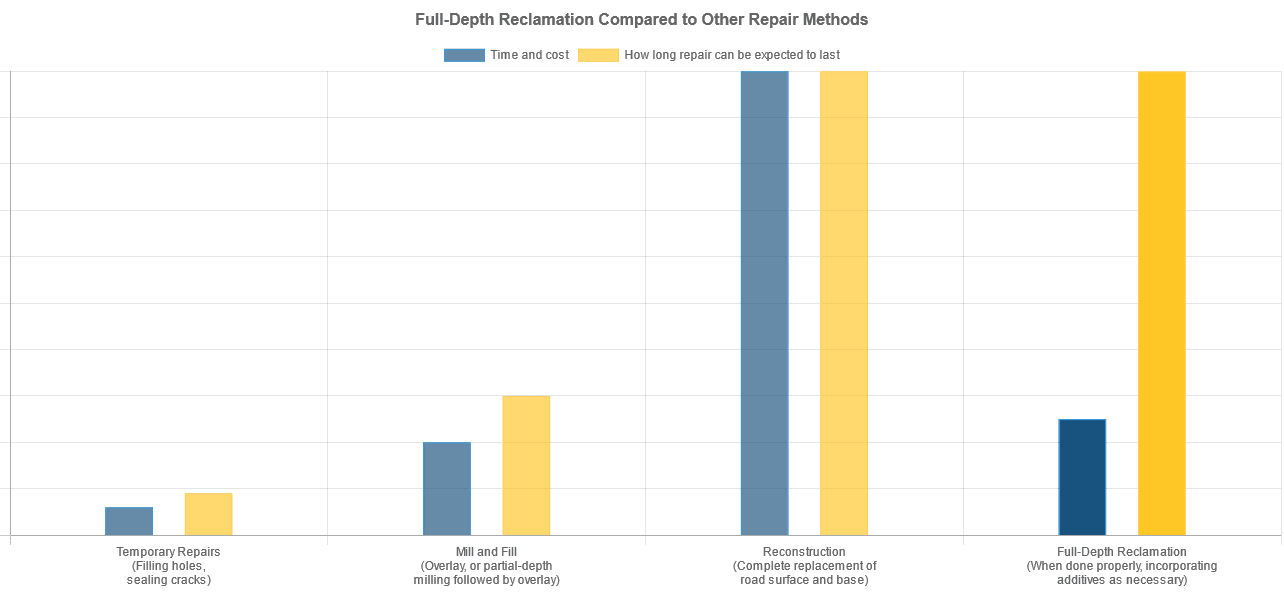

Economic benefits are another reason many organizations choose full depth reclamation. Temporary repairs like filling potholes are cheap and fast, but short term, creating a never ending cycle of repair.

FDR vs Traditional Repair Methods

Mill and fill asphalt methods use an asphalt milling machine or cold planer to remove the decaying asphalt. Next crews apply a surface layer of asphalt. Unfortunately, road base problems cause most alligator cracking and potholes. Mill and fill road repairs often result in the same cracks or potholes reappearing in the same place.

Another road repair option is at total road reconstruction. This method is much more time consuming and costly than mill and fill.

This process involves the demolition and removal of the asphalt and road base. Next crews work to level and slope the ground. Then they apply a new sub base and binder layer. Finally, they pave the road with asphalt.

Road reconstruction takes a significant amount of time and causes long term traffic disruption. It also sends more asphalt product to landfills and requires additional aggregate road base. Because of these factors, a complete road reconstruction is also extremely expensive.

Full depth reclamation hits the sweet spot between traditional mill and fill asphalt repairs and full road reconstruction. FDR takes only slightly more time than a mill and fill project, but the results last as long as a full road reconstruction. Reusing old asphalt for roads is good for the environment and saves money for projects. Many organizations report saving 70% or more by recycling their worn out roads.

Learn More About a Road Reclaimer Attachment Today

Full depth reclamation produces high quality long term road repairs at a fraction of the cost of traditional repairs. Depending on soil conditions and other factors, you have the flexibility to choose between basic, chemical, or mechanical stabilization. Also, re-using existing materials and recycling asphalt product makes it more sustainable.

Portable asphalt reclaimer attachments make FDR possible for even smaller organizations. This allows them to stretch their road construction budgets and achieve more high quality and longer lasting road repairs. Visit Asphalt Zipper.com today to learn more about our road reclaimer attachments.