Eco-friendly road repairs: How sustainable practices benefit cities and citizens

Most people never notice how much work cities do to keep streets safe and smooth. But they definitely notice when the roads are in disrepair. Residents want less road construction and at the same time fewer potholes, a seemingly impossible conundrum. Worse still, tight budgets, aging pavement, and workforce challenges are making road maintenance increasingly challenging for most communities.

The good news is that many cities are finding ways to eliminate more potholes with shorter construction disruptions. They are also discovering methods to achieve better results by shifting to environmentally friendly road repair methods. These approaches use recycled material to cut waste while stretching maintenance dollars. Tools like asphalt milling machines, asphalt grinders, cold planers, and asphalt reclaimers make it easy to recycle old pavement. This helps build a stronger road with existing material without the need for constant hauling and disposal.

You can think of this as a change in mindset. Asphalt road maintenance used to focus on removing the old pavement, trucking it away, and bringing in fresh material. That produced a lot of asphalt disposal, heavy truck traffic, and long closures.

Now crews rely more on asphalt pulverization and pavement recycling using a reclaimer machine. When a cold milling machine or asphalt grinding machine removes the surface, the reclaimed asphalt pavement RAP can stay onsite. This RAP recycled asphalt product can be reused as part of a recycled road base. The process is cleaner, faster, and far more efficient for everything from a pothole repair to a large construction project.

The biggest benefits come from a road repair method called full depth reclamation. This method does far more that surface asphalt repairs. A road reclaimer pulverizes the pavement and simultaneously blends it with the road base layer. This homogenous blend of reclaimed materials helps stabilize the road base.

Quite often the recycled road surface blended with the existing road base material is sufficient for base stabilization. Most potholes, ruts, and cracks are generally the result of road base issues. By stabilizing the road base, the road surfaces will last much longer.

Cities like this approach because it solves the root cause of many road maintenance issues. FDR improves road stability and helps asphalt and chip seal road surfaces last years longer.

Studies show that reclaimed asphalt pavement used as a fresh base can significantly reduce life-cycle costs and improve smoothness over time. For agencies with long maintenance backlogs, this matters. In fact, a 2024 report by the Colorado DOT states, “On average, the life-cycle cost of FDR pavements is $178,243/ln-mi less expensive than overlay pavements, resulting in a potential cost savings of 30%.

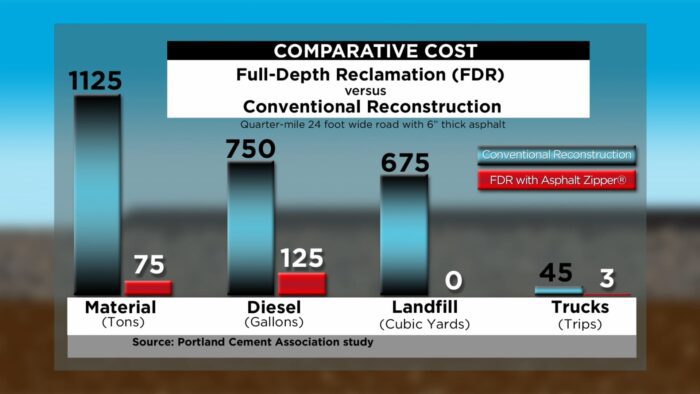

In addition to lowering costs, recycling asphalt pavement eliminates a significant amount of CO₂ emissions. A Portland Cement Association study illustrates this by comparing conventional reconstruction to full-depth reclamation. An FDR project on a quarter mile 24 foot wide road uses 1050 fewer tons of material, 625 fewer gallons of diesel, 42 fewer truck trips, and 675 fewer cubic yards of landfill space. This equals almost 7 tons of CO₂ reduction.

Less material, less fuel, and fewer truck trips also means substantially less time and money spent per project. Full-depth reclamation gives municipalities a way to adopt greener practices while saving budget dollars.

Getting started with full-depth reclamation does not require a major shift for most communities. The first step is identifying which streets could benefit from in-place recycling or full depth reclamation.

Residential and arterial roads are often great candidates. By using reclaimed asphalt pavement as recycled road base, municipalities can do many more projects on the same budget. This helps elected officials see clear long-term value in each project.

In addition to this, citizens get smoother travel and less wear on their vehicles. When cities focus on recycling asphalt, managing asphalt disposal responsibly, and building stronger asphalt road base structures, everyone benefits from the improvements.

The bottom line? Asphalt recycling with full-depth reclamation has important environmental benefits and can significantly stretch your road repair budget. It also stabilizes your roads, leading to fewer future repairs.

Eco-friendly road repair is now a practical, proven approach for cities that want reliable results. Using asphalt grinders, cold milling machines, asphalt recycling machines, and road reclaimers helps crews better utilize materials on-site. By emphasizing full depth reclamation, asphalt recycling, and in-place pavement rehabilitation, municipal teams can deliver more durable roads, less waste, and meaningful savings for the people they serve.

Your residents may never appreciate all of the work that goes into smooth, well-maintained roads, but they will definitely notice the results. And behind the scenes you achieve the seemingly impossible: fewer potholes, and less road construction, and a lower carbon footprint.

Google Takeaways

• Asphalt recycling cuts waste, lowers asphalt disposal, and keeps reclaimed asphalt pavement on-site.

• Full depth reclamation strengthens the asphalt road base for long-lasting, low-cost repairs.

• Asphalt grinders, cold milling machines, and road reclaimers reduce hauling, emissions, and project time.

• Recycled road base improves soil stabilization and prevents potholes, cracks, and ruts.