If you’re uncertain about the difference between cold in-place recycling (CIR) and full depth reclamation (FDR), you aren’t alone. Both are forms of asphalt recycling and reclaiming used as an alternative to asphalt patching and full road repair.

To add to the confusion, there are additional regional terms that have the same meaning. For example, CalTrans, California’s department of transportation, places the processes of FDR and CIR under the umbrella of cold recycling, and refers to FDR as full depth recycling, and CIR as partial depth recycling. This makes it even more important to distinguish between cold in-place recycling and full-depth reclamation. Both road repair methods use recycled asphalt pavement, but their processes and results are significantly different.

Some of these differences lie in the depth of the recycling and the process and equipment you use. Full-depth reclamation recycles the asphalt or road surface and a portion of the road base with a road reclaimer. Cold in-place recycling uses a cold planer, asphalt milling machine, or asphalt reclaimer to recycle only a portion of the bound asphalt layer, usually 2 to 4 inches deep.

The history of the two terms sheds light on their meaning. An archived Federal Highway Administration (FHA ) publication states, “Cold In-place Recycling (CIR) is defined as a rehabilitation technique in which the existing pavement materials are reused in place. The reclaimed asphalt pavement (RAP) material is obtained by milling, planing, or crushing the existing pavement.”

At the time of the publication, it was possible to perform asphalt recycling at full or partial depths. Full depth recycling included the asphalt and portions of the base. Partial depth recycling involved removing and reusing 2-4 inches of asphalt.

In recent years, advancements in cold milling equipment and processes have allowed crews to recycle much deeper into the road base. Because of these advancements, the FHA accepted the definitions from the Asphalt Recycling and Reclaiming Association (ARRA). “ARRA defines cold in-place recycling as a partial depth recycling process involving 3 to 4 inches of the existing pavement. [It] defines full depth recycling as full depth reclamation (FDR) which is considered a separate procedure.”

Based on this information, FDR and CIR are considered different processes. However, both use recycled materials on road construction projects. And prior to advancements in asphalt grinding machines / road reclaimers, both fell under the category of asphalt recycling. Let’s shed some light on the processes by looking at their similarities and differences.

Cold In-Place Recycling Process

Definition

The ARRA states that cold in-place recycling mills 2-5 inches of asphalt. It recycles this material using a “train” of equipment. The existing material then becomes new asphalt paving. It is less expensive that a full road reconstruction and significantly reduces greenhouse emissions. This form of pavement rehabilitation can produce long-term road repairs that last up to 15-20 years.

Process

Cold in-place recycling generally involves multiple pieces of equipment forming a “train.” At the front is the asphalt milling machine which mills the roadway. Less common is a single piece train, where the same equipment adds a recycling agent into the asphalt grinder chamber. In either scenario the “train” then spreads the mixed asphalt and emulsions onto the roadway as pavement with an attached screed.

Two-piece trains mill the roadway and transfer the asphalt millings to a separate machine. This mix paver mixes in a recycling agent and paves the road.

Multiple piece trains have additional pieces of equipment that assist with the material sizing. They can also add the desired mix design and pave with separate equipment.

Full-Depth Reclamation Process

Definition

Using a road reclaimer/recycler, road stabilizer or asphalt grinder, full-depth reclamation pulverizes the entire road surface and a predetermined depth of the road base. This can create a stabilized road comparable to a full road reconstruction.

Full-depth reclamation uses 100% of existing materials and boasts cost and time savings of up to 70% or more. It can also extend the life of pavement for up to 25 years. The difference between FDR and CIR lies in the process and equipment.

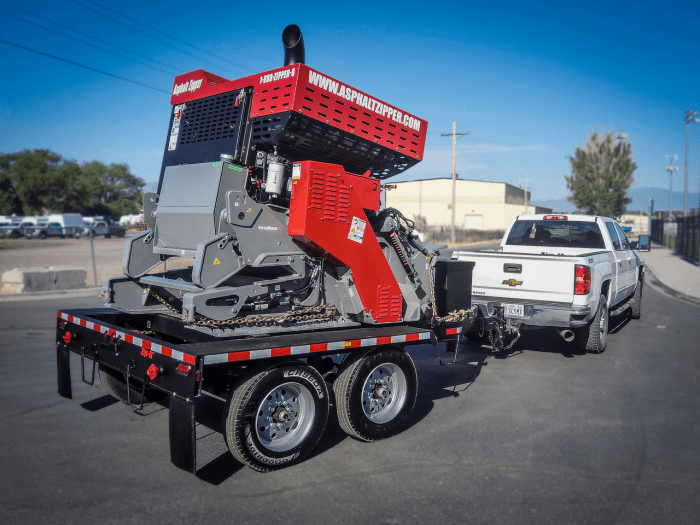

Full-depth reclamation uses a road reclaimer or portable road reclaimer attachment to reclaim worn asphalt or chipseal surfaces into spec comparable base material. This material can be simultaneously blended in-place to stabilize the road base. Often, this reclaimed material from the ground road surface alone is enough to stabilize the road base.

When it isn’t sufficient, crews can calculate the road base and spread additional aggregate material over the road surface prior to reclamation. Called mechanical stabilization, this provides additional stability to the road base. You can also use chemical stabilization. This involves adding lime, fly-ash, Portland cement, or other additives to further stabilize the road base.

After performing full-depth reclamation, crews use a grader to shape the road for optimal drainage. Portable road reclaimers may come with their own water system. If using a larger self-propelled reclaimer, crews will also need a water truck to wet the road. Finally, they compact and apply a new pavement surface in a separate process with separate equipment.

Benefits of Full-Depth Reclamation

- You are recycling the asphalt or chipseal surface into spec comparable base material. This means you don’t need to haul out asphalt chunks or haul in new aggregate material.

- Most potholes, ruts, and cracks are the result of road base problems. By addressing the road base, you ensure that the new high quality road surface will last much longer.

- An asphalt reclaimer attachment is a powerful asphalt grinding machine. It transports behind a work truck and is ready to go in minutes, eliminating costly transport of larger equipment.

Conclusion

While both cold in-Place recycling (CIR) and full-depth reclamation (FDR) fall under the category of asphalt recycling, their processes during asphalt recycling differ significantly. Full depth reclamation pulverizes the existing pavement and uses it to address road base issues. Cold in-place recycling mills a portion of the asphalt surface which it mixes with additional additives. It does not address the road base, but it uses the asphalt millings to pave the road as part of the process.

FDR and CIR serve different purposes depending on the depth and condition of the road. CIR focuses on rehabilitating the upper layers of asphalt for cost-effective, mid-term road performance, while FDR rebuilds the entire pavement and base for long-lasting structural stability.

Communities, contractors, and agencies can choose the right method based on project scope, road conditions, and budget. Either way, both approaches reduce waste, save money, and extend the life of our roads through smarter recycling.

Google Take-A-Ways

Cold In-Place Recycling (CIR): Recycles 2–5 inches of asphalt pavement using a train of equipment.

Full-Depth Reclamation (FDR): Pulverizes the entire asphalt layer plus part of the road base with a road reclaimer.

Lifespan: FDR can extend pavement life to 25 years or more.

Cost Savings: Both methods can reduce project costs by 50–70% compared to reconstruction.

Sustainability: Both reuse 100% of existing materials, cutting waste and greenhouse emissions.

Key Difference: CIR rehabilitates only the asphalt surface, from removing the asphalt to putting down recycled pavement. The FDR process rebuilds the road base for long-term stability. Paving following FDR is a separate process.