Did you ever think the day would come when you would have the money for road repairs but not enough workers? Or maybe you’ve got the workers, but they would rather contract out road projects? If this problem hasn’t hit you yet, it might soon.

A shortage of road crew workers across the U.S. is one of the many challenges making it difficult for cities and towns to repair their roads. Unfortunately, those potholes keep popping up, and the search is on for innovative cost and time-saving road repair technology and equipment. Full-Depth Reclamation is one road repair method that allows municipalities to complete more road repair projects with fewer crew member in less time.

Full-Depth Reclamation (FDR) is a road repair solution that can help counteract manpower shortages on projects. The FDR process is a quick, simple, and long lasting road repair and road base stabilization method that gets better results than pot hole patching or full road reconstruction with fewer steps and labor.

Full depth reclamation involves pulverizing worn asphalt or gravel roads while simultaneously mixing them with the road base. This results in a more stable road base and, assuming there is adequate base material in place, eliminates or greatly reduces the need for hauling in additional aggregate material and hauling out worn asphalt chunks. Because the process reuses recycled asphalt product (RAP) as road base, a road repair job requires fewer steps, supplies, and workers. This makes it a valuable tool when you can’t find a road worker under the age of 60.

Understanding the Manpower Shortage in the Construction Industry

The U.S. Chamber of Commerce reported in February of 2024 that there are 9.5 million jobs available nationwide, but only 6.5 million unemployed individuals. One of the hardest hit industries is the construction industry. With a $1 trillion infrastructure bill signed into law in November of 2021, there is money to repair roads, but with workers AOL, projects take longer to complete and become more expensive.

COVID 19 definitely contributed negatively to the number of people applying for construction jobs. In fact, between 2019 and 2020, that number fell by 40% and hasn’t recovered. Money speaks, and workers headed to larger corporations where they could make more money and have better benefits. Some people opted for (air conditioned) remote work with greater flexibility. Others left during the COVID 19 pandemic and never returned to the workforce.

Another concern is the fact that older workers are retiring at a greater pace than young workers can take their place. Skilled labor is also an issue. Although the infrastructure bill funds large and badly needed road repair projects, it doesn’t fund training for new workers. Most 18-year old kids don’t know how to hold a shovel, let alone repair a road.

These challenges make it even more important to find innovative and efficient methods to get more done with fewer people in less time. Full Depth Reclamation is one of those innovative methods, facilitating more with less.

Introduction to Full-Depth Reclamation (FDR)

Full Depth Reclamation is a road repair method that addresses road surface problems like potholing and alligator cracking. It does this by strengthening the road base, the real problem behind most potholes and alligator cracking. Traditional asphalt patching and pothole repairs are temporary. Sooner or later those pesky potholes will reappear in the same place. Road base stabilization provides a longer-term fix for potholes and alligator cracks.

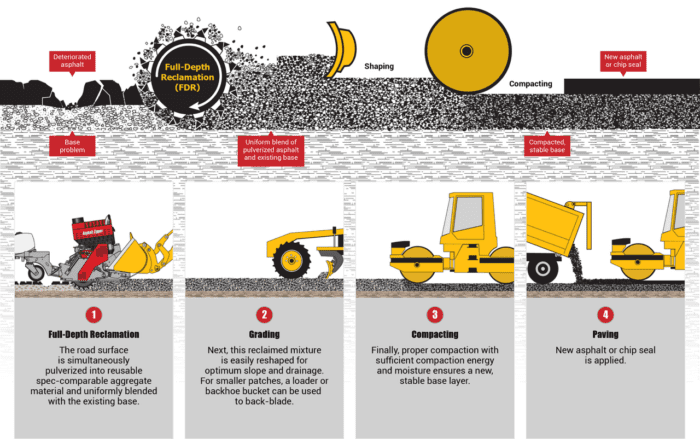

Basic full-depth reclamation utilizes a road reclaimer to pulverize the road surface into spec-comparable reusable aggregate material and blend it with the base. After grading, compaction with water, and paving, FDR creates a new, stronger road base.

If this approach is not enough, mechanical stabilization spreads additional aggregate material on the road surface, which is pulverized with the asphalt and road base. Mechanically stabilized road base further strengthens the asphalt surface.

Chemical soil stabilization is also an option. With chemical stabilization of soil, road crews perform basic stabilization first and then apply a chemical additive such as Portland cement. They blend this additive to the same depth as the basic stabilization on a second pass for an even stronger road base.

Benefits of Full-Depth Reclamation

- Projects are completed up to 70% faster than traditional road repair methods. Because of the fast completion time, full-depth reclamation is also significantly less expensive.

You’re already saving money with those open road crew positions. Why not do more projects at the same time? - Using a road reclaimer to recycle asphalt as road base conserves natural resources in the form of aggregate material. It also reduces carbon emissions from asphalt disposal and hauling in additional road base material. “Green” talk aside, now you don’t have to find another guy to drive the dump truck.

How does Full-Depth Reclamation Reduce Manpower Requirements?

· Faster Project Completion

FDR speeds up the road reconstruction process by eliminating the need for asphalt cutting and chunking. Instead, an asphalt recycler or road reclaimer pulverizes the asphalt into reusable aggregate material.

This also avoids or reduces the need for material hauling which uses additional manpower. Even if you operate on a skeleton crew, you can still do the same number of projects because you finish them so much faster.

· Integrated Process

Full-depth reclamation combines several steps into one streamlined process. This reduces the need for specialized labor and multiple crews. FDR is a simple process that even a rookie can learn.

· Use of Advanced Machinery

Road reclaimers do the work of asphalt removal and road base stabilization in one step. Fewer workers operate these asphalt recyclers, making projects less dependent on a large workforce. A large road reclaimer may be too expensive for a smaller organization, even one saving money on salaries. Asphalt milling and reclaiming attachments are much less expensive and connect to a backhoe or loader. They can perform as well as larger road reclaimers.

Long-Term Benefits of Full-Depth Reclamation

- FDR is a more cost-effective road repair process. It provides long-lasting road repair benefits for a fraction of the cost of traditional repairs.

- FDR is a simpler road repair process that requires fewer steps and fewer laborers. This allows organizations to use their employees more efficiently and operate with smaller crews.

- FDR makes organizations more efficient by enabling them to complete projects faster with fewer resources. This in turn leads to smaller project budgets and the ability to complete more projects in the same amount of time.

Implementing a Full-Depth Reclamation program could be the solution to your manpower challenges. Its efficiency allows organizations to complete jobs more quickly so that you can get more done with fewer people.