One of the top priorities of local and state governments is road maintenance. Yet according to Pew Research, state and local road departments experienced a budget shortfall of $105 billion between 1999-2023. This means that annual wear and tear on roads and bridges is briskly outpacing spending on preservation and maintenance. If road maintenance is so important to cities and towns, why is it getting the short end of the budget stick?

Small budgets, pothole-ridden roads, and manpower issues all contribute to the problem of deteriorating roads. Communities are looking for solutions for both patching roads and reconstruction. They want road repairs that last a long time, that are affordable, and that they can do quickly. It just so happens that using the right equipment and processes can give cities and towns of all sizes the ability to do just that.

Extend the Life of Road Repairs

with Asphalt Recycling and Reclaiming

Failing road base causes most potholes, ruts, and alligator cracks. Unfortunately, many communities treat only the surface layer of the pavement, sealing cracks and filling potholes. They might also use an asphalt milling machine / cold milling machine to mill a few inches off the surface of the asphalt. Then they repave with a fresh asphalt surface in a process called mill and fill.

While asphalt grinding the surface might provide a smoother ride short-term, most likely the same potholes will eventually reappear. Asphalt grinder attachments can do surface milling, and this might be enough for some roads. However, what many communities don’t know is that the same asphalt grinding machine is also a powerful road reclaimer.

Asphalt grinders /asphalt recycling machines recycle the road by pulverizing the worn asphalt and chip seal into spec comparable base material using a process called Full Depth Reclamation. The reclaimed asphalt pavement can be simultaneously blended in place with the underlying base to help stabilize the road base, extending the life of the road.

The reclaimed road will last much longer with significantly less maintenance. In fact, using recycled asphalt pavement or asphalt millings also lessens the need to purchase new aggregate materials. It turns out that using recycled materials is good for both the budget and the environment.

Affordable Full-Depth Reclamation In-House

Smaller municipalities might feel they cannot afford full depth reclamation. They also might be concerned that they do not have the crew or equipment to perform high quality full-depth reclamation in-house. However, portable road reclaimer attachments make asphalt reclamation simple enough that even a two to three man crew can be successful. Also, if cities do the work themselves with their own crews they can experience cost savings of up to 70% or more, compared to contracting out the same road repairs.

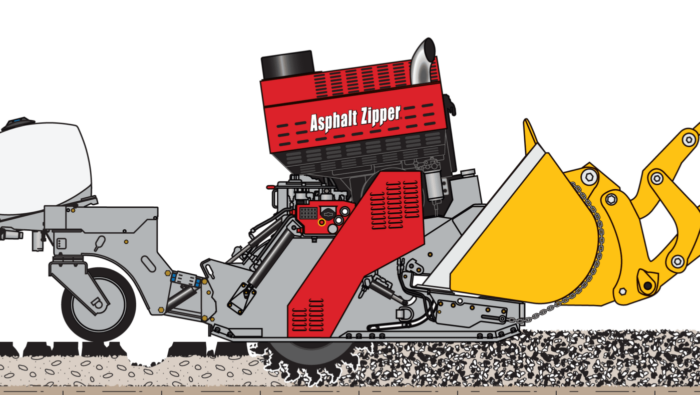

The process is quite simple. The small asphalt milling machine / road reclaimer attaches to the bucket of a loader or backhoe. One crew member operates the loader while another crew member acts as groundsman. See how it works here.

Following the reclamation process, the crew grades the road, adds water and compacts it. A maintenance seal of either asphalt or chipseal comes next, resulting in a smooth road that will last up to 10 to 20 years or longer.

Quick and Efficient Pothole Repairs with Asphalt Reclaimer

Another issue facing cities and towns is completing repairs quickly. No one wants road repairs that drag on and the resulting unhappy citizens. In-house full depth reclamation provides almost continuous access to businesses and residential areas.

A number of factors make this possible. First, owning a road reclaimer gives street departments the flexibility to schedule their road repairs and do smaller repairs. This creates less disruption from on-going construction.

Another factor is the quick process. Communities report being able to complete road projects in just a few hours. Some residents don’t even notice the construction until they are driving on a smooth road. A third factor is the reclaimed asphalt product created during the full depth reclamation process. The recycled asphalt product can easily be driven over making road closures unnecessary in many cases.

Conclusion

By reclaiming and recycling asphalt in-house, municipalities can take control of road repairs. This allows them to stretch their budgets and deliver longer lasting results. Full-depth reclamation reduces material and contractor costs. It also saves time and limits disruption to the public.

With the right equipment even the smallest towns can repair roads efficiently and cost effectively. This reduces long-term maintenance and improves the quality of their infrastructure, all without breaking the bank.

Google Take-a-Ways

- Full Depth Reclamation Saves Up to 70%.

- Small crews can use Asphalt Reclaimers in-House with great success.

- Full depth reclamation rebuilds the road base—unlike asphalt grinding just a road surface—preventing future potholes.

- While mill and fill can create smooth roads, road reclamation can create more durable longer-lasting results.

- Reclaimed asphalt is drivable during repairs, cutting down on road closures and public complaints.

- Using reclaimed asphalt product reduces the need for new materials and lowers overall project costs.

- Compact asphalt reclaimer attachments fit on loaders or backhoes, making them ideal for municipalities.