Road repair is a constant concern for every city and town. When freeze and thaw cycles lead to potholing or alligator cracking, road crews have to fix the damaged road surface. Many road departments resort to a road patch, putting a temporary band-aid over the cracked asphalt.

Unfortunately, soon new potholes form because road base failure itself causes cracked asphalt. Then, fixing the asphalt surface becomes a never ending cycle of road repair.

Street departments may also remove the surface of the failing asphalt. Then they apply a thin layer of asphalt. Although there are many benefits of asphalt milling, surface asphalt milling only addresses the visible problem on the asphalt pavement.

Most road surface problems are actually a result of road base problems, rather than the asphalt surfaces. Pavement milling only treats the surface. But the underlying problem persists, and you have to do the same repairs again and again.

Traditional Road Repair Methods

Traditional road reconstruction involves asphalt removal with saw cutting, chunking, loading and hauling. Road crews then haul in construction aggregate for new road base material and pave the road surface with fresh asphalt. This is an expensive, not a cost effective road repair option.

Traditional road reconstruction is also bad for the environment because it doesn’t involve asphalt recycling. The asphalt may end up in a land fill, and its hauling contributes to vehicle emissions.

In addition to this, purchasing and hauling new road material or aggregate material is expensive and depletes the environment.

Full Depth Reclamation

Using full depth reclamation for road base stabilization addresses asphalt rutting, potholes, and alligator cracks by fixing the base. City and county road departments are discovering that doing road repairs in house can save a substantial amount of time.

One of the initial investments involved in full depth reclamation is a road reclaimer or milling machine. An asphalt reclaimer pulverizes the existing asphalt into fine aggregate. This spec comparable material mixes with the existing road base.

Often, you don’t need to add additional soil stabilizers. The recycled asphalt pavement creates a more stable road base, meaning fewer asphalt failures.

Next, road crews reshape and grade the combined recycled asphalt and road base mixture to create recycled road base. They frequently add water to increase moisture content and better bind the new road base. Finally it is important to compact the mixture to produce a new and stable road base of reclaimed asphalt pavement rap.

Advantages of Asphalt Recycling

A road reclaimer can seem like a large purchase to a smaller city or county road department. Although milling equipment is an investment, a road reclaimer quickly pays itself off in time and cost savings.

A road reclaimer eliminates the purchase of road fill and aggregate materials. This equals a 100% savings on new road base material.

Full depth reclamation road repairs also last longer. In addition, you will also be able to do more repairs on the same budget. In fact, cities and counties report saving 70% or more on their road repair budget.

You will eliminate saw cutting. Because of this, you will save up to 90% on fuel and emissions reduction. Best of all, your road repairs will be long lasting with a stable road base. This means you can spend your resources on full road repair instead of pothole patching.

Portable Road Reclaimer Attachments

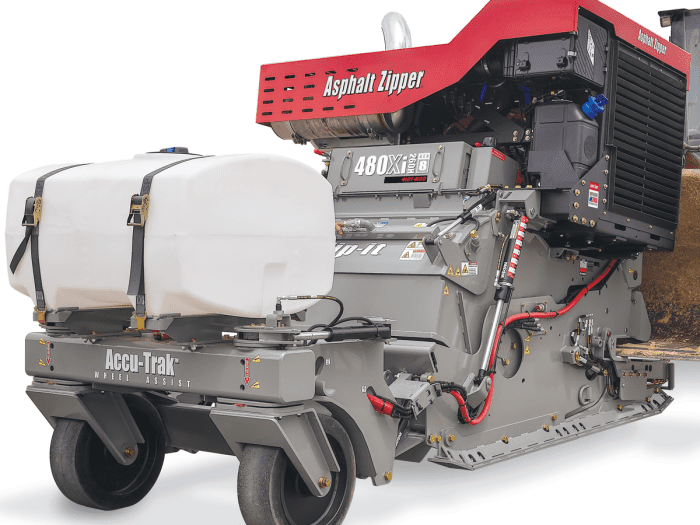

Even with these incentives, a large self contained asphalt reclaimer might be too much for your budget. You may not be aware that there are portable road reclaimer attachments that connect to your backhoe or loader.

With 260 hp tier 4 engines, these road reclaimers compare to larger asphalt reclaimers, cold planers and asphalt milling machines. The 6-8 foot cutting widths and 12 inch cutting depths allow these asphalt reclaimer attachments do the work of larger machines.

You can pull these attachments on their own trailer, making them easy to transport. These asphalt reclaimers are substantially less expensive than larger models, but they produce the same full depth reclamation results.

Full Depth Reclamation is for Everyone

Road reclaimer attachments allow cities and counties of all sizes to end the cycle of temporary road repairs. They can now repair their road base for a fraction of the cost of traditional road reconstruction methods.

This provides a more permanent solution to pot hole repair and alligator cracking. The asphalt recycling involved with full depth reclamation is also more green road repair. This is why more cities and counties are bringing their road repair in house.